The lifespan of electric vehicle batteries depends on cycles and taking care of them thermally. This blogpost series dives into the battery thermal management. I’ll start off with an introduction to the topic in this post and discuss “What is the ideal battery temperature?”. First from a usage / discharge perspective and then for charging. In the next posts I will look at what various OEM’s like Tesla, Nissan and Chevrolet do and what we can learn from them. After that I will share my own implementation in a DIY setting. Finally I will gather and share some real world temperature data.

Battery discharge temperature

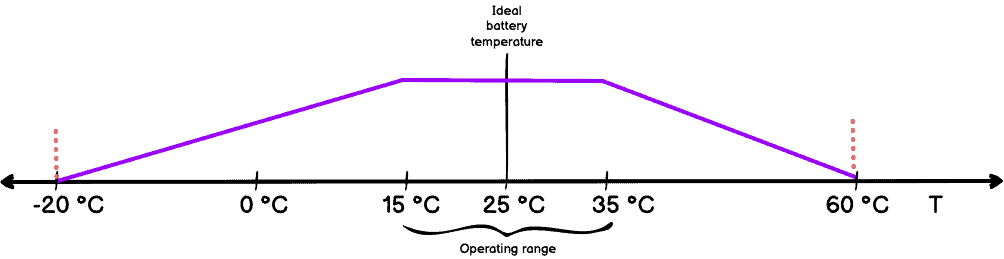

The amount of usable energy from a battery decreases with decrease in temperature. This impacts range and performance of an electric vehicle. In the below graph the discharge current is visualized over temperature.

The desired operating temperature of a lithium-ion battery in an electric car is 15 °C to 35 °C. Below 15 °C the electrochemistry is sluggish and the available power is limited. A significant and noticeable difference probably starts at temperatures below zero degrees. In the upper temperature region it is not the battery limiting the available power. Instead the electric vehicle should limit power to minimize further temperature increase and prevent degradation or worse, thermal runaway. The ideal battery temperature for maximizing lifespan and usable capacity is between 15 °C to 35 °C. However, the temperature where the battery can provide most energy is around 45 °C.

Impact of battery temperature on available capacity

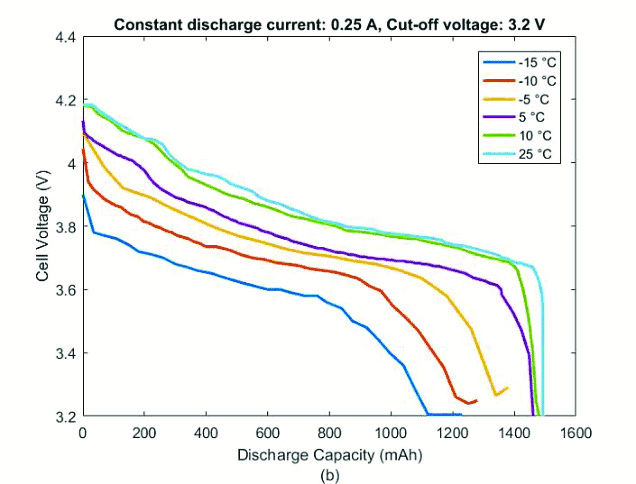

University research of a single cell shows the impact of temperature on available capacity of a battery in more detail. The below data is for a single 18650 cell with 1,5 Ah capacity and a nominal voltage of 3,7V (lower cut-off 3,2V and upper cut-off 4,2V).

The researchers measured voltage and capacity at various temperatures while discharging.

Graph / data source: Mohamad Aris, Asma & Shabani, Bahman. (2017). An Experimental Study of a Lithium Ion Cell Operation at Low Temperature Conditions. Energy Procedia. 110. 128-135. 10.1016/j.egypro.2017.03.117.

From that research paper and the above graph it becomes apparent that at -5 °C only 92% or the full capacity remained. At -10 °C it was only 85% and at -15 °C it was reduced further to 82%. Other studies show even a bigger impact.

These losses in capacity are mainly due to the increase of internal resistance that causes a warming effect to the cell. The good news is, the ‘problem’ partially solves itself. By using / discharging the batteries they heat up. On the other hand, when it is cold you will probably have a higher energy demand. For example to heat the interior which decreases available capacity and thus range even further. Therefore I implemented a stationary heater (details later in the DIY post).

Impact of battery temperature on lifespan

High and low temperatures outside the ideal operating range not only have an impact on available capacity but also on the lifespan of the battery. Whereas low temperatures mostly result in reduced available capacity, high temperatures lead to battery degradation.

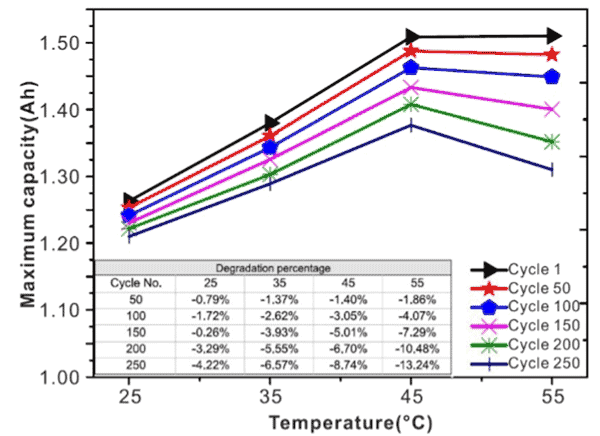

The below graph is from a different study where a prismatic 1,35 mAh cell from Sony with a nominal voltage of 3,6V was used. As a result it is not 1:1 comparable with the graph above but does provide a good impression.

The researchers looked at the maximum charge storage capacity over a number of cycles (times a battery is fully charged and discharged) for various temperatures.

Graph / data source: Effect of Temperature on the Aging rate of Li Ion Battery Operating above Room Temperature, Feng Leng, Cher Ming Tan & Michael Pecht (2015) Nature.com Scientific Reports

From that graph and research paper we see that at higher temperatures we do get a higher maximum usable capacity. However the downside is that the maximum capacity reduces (quickly) as the number of cycles increases.

Charging batteries and temperature

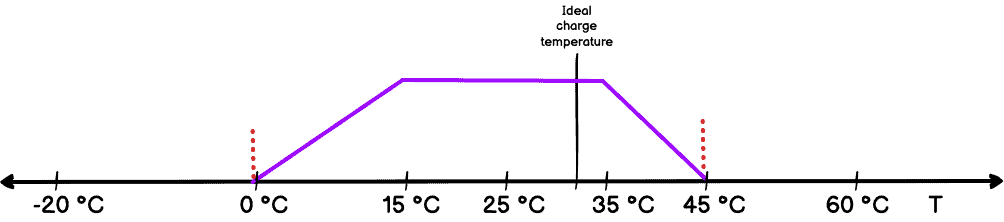

The implications for charging batteries are even bigger. To maximize the lifespan of lithium-ion batteries they should not be charged at temperatures below zero degrees or with very low current only (trickle charge). Also at low temperatures just below zero a conservative charging current is appropriate. This is visualized in the graph below.

In particular while DC fast charging, cooling or even active cooling might be needed.

The fact that one cannot charge lithium-ion batteries below 0 °C not only has an impact on the process of charging a car, but also on driving it. Regenerative braking = charging the batteries. So the vehicle control unit (VCU) should take this into account and the driver will have to use hydraulic braking more often when the battery pack still is cold. Limited regenerative braking possibilities is another reason for reduced range during winter.

Ideal battery temperature?

Does an ideal battery temperature exist? From the data in the research summarized above we can conclude it is a tradeoff between maximum usable capacity and preventing battery degradation. While at 35 °C the maximum available capacity increases, at the same time it also accelerates the degradation. In conclusion: 25 °C often is the ideal battery temperature and balances between capacity and lifespan. For fast charging the ideal temperature is 32 °C. However since charging also generates heat (active) cooling is needed. Otherwise a lower temperature and matching current is best for charging. And again, no charging at all at temperatures below zero.

Liquid or air battery cooling/heating

There are two approaches for managing battery temperature: air or liquid. Briefly we will summarize the advantages and disadvantages of the two below.

Battery heating and cooling using air

There are a couple of advantages of the air cooling/heating approach. It is simple and cheap. It does not add much weight, design and manufacture complexity or many points of failure. Furthermore is there no risk of leakage and thus no risk of electrical short by (often) conductive coolant. And above all, in the end all waste heat needs to be dissipated to air anyway.

Unfortunately, “There ain’t no such thing as a free lunch”. The air cooling approach also has some significant downsides. First of all the heat (transport) capacity is low. Secondly routing air along individual battery cells or pouches is challenging. As a result there will be more temperature variation in the battery pack. In addition air cooling or heating requires the use of strong blowers that are potentially noisy.

Liquid battery heating and cooling

The main advantage of using a liquid for battery cooling and heating is the excellent heat (transport) capacity. A heat exchange plate or tube in between cells can quickly add or absorb heat. In addition the more a heat exchanger integrates in between the cells, the higher this capacity is. As a result the temperature in a battery pack distributes more evenly and thus enhances the thermal stability.

However, liquid cooling does add more complexity. It requires more components which can fail and cause errors. In addition it adds costs and weight. As a result it potentially requires more maintenance. In other words, more effective heat exchange does come with a price.

In the next post we will look into how Tesla manages battery temperature.

Blog series on battery thermal management

- Ideal battery temperature?

- Using Tesla thermal management parts

- Other OEM thermal management

- Example of DIY approach

- Battery temperature data in practice

Feedback welcome

Any feedback, additions, suggestions for improvement is welcome. Please contact me by e-mail.

Share & link

Do you like this article? Please share and link (and not copy paste).

Thanks for sharing this full of a knowledge article. I am a Shopkeeper, and my hobby to read the articles about batteries. Such a lot of new things described in it. I also really like the graph that you used in “Charging batteries and temperature.”

Thanks again for sharing this.

JOHN EMMONS

Great summary – I’ll share this !! on Twitter: @77A